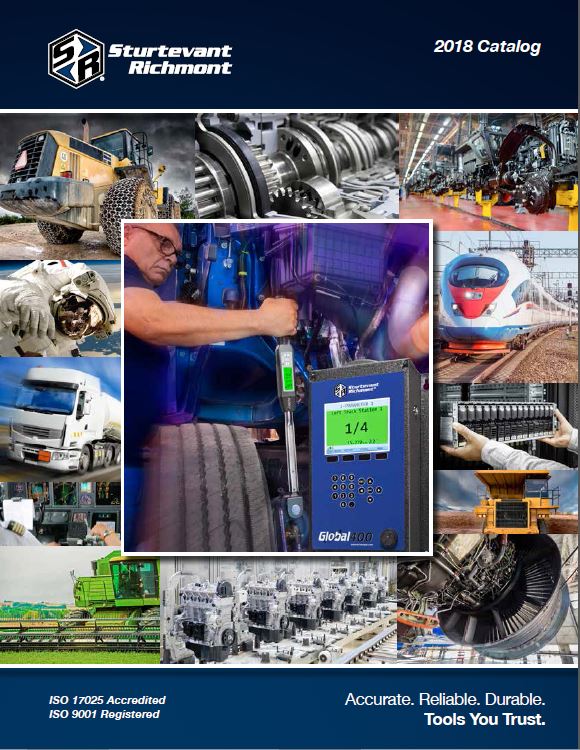

Sturtevant Richmont

Global 400

Torque Controller System

Order Global 400, Part No. 10497

Literature

Mixed Model Manufacturing

Mandates Flexibility:

We specialize in solving the most complex assembly challenges.

The Global 400 is designed to organize

highly customized products are assembled. It can work with

16 primary torque tools, 8 holding tools, and an additional 8

I/O tools. It has the capacity for 100 sets of parameters that

can be grouped allowing 4 operators to work as a team. These

parameters or groups can be formed into jobs containing a

fixed build sequence of up to 35 steps.

Mixed Model Manufacturing

Mandates Communication: The Global 400 communicates with the operators, the tools,

and your network in multiple ways. Parameters or jobs can be

assigned via the Ethernet or by the operator via a bar code

scanner. Tools can be selected or programmed wirelessly, while

the controller displays the required work to the operator. As

the operator works through their task, the tools and controller

provide auditory, tactile, and visual guidance. The tools provide

the controller with immediate notification of operator results. The

controller stores up to 10,000 results in

automatically updates your production system via multiple

protocols. No production interruptions!

System Capabilities:

• Six

45 Ethernet ports allow for chain, or ring network

communication.

• USB-A connector for use with

• RS-232 D-Sub9 Connector for use with serial bar code

scanner or serial printer.

•

•

optional GIM400.

• Power Supply 100-240 VAC at 50-60 Hz.

• Key switch for programming access. 21-function keys for

programming.

• Adjustable and programmable beeper for audio

communication.

Protocols: EtherNet IP, Open Protocol,

Software: SR Global Manager (Included) optional SR

Enhance your controller with

our GIM400 Global Input/

Output Multiplier, part number 10611.